🇫🇮 SelectAM Has Launched a Seamless End-to-end Workflow from AM Part Identification to the Delivery of Manufactured Parts

Press release from FAME

SelectAM’s AI-powered platform is from now on available as a free open-access version, which allows users to assess large numbers of CADs and part-related data to identify and order AM business cases. The user can get instant AM price quotes and lead times for single parts and assemblies, perform a quick total cost of ownership (TCO) assessment including calculations for conventional manufacturing, estimate your AM saving potential, run mesh integrity checks, and evaluate the overall input data quality level. As shown in the video, these features are provided free-of-charge without any necessary sign-up. Users’ data is neither stored on any server nor collected.

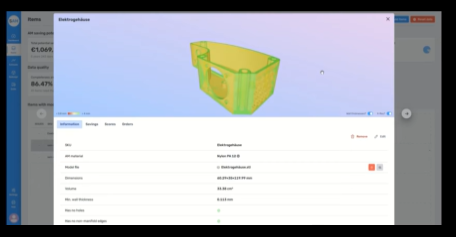

If you are an owner of AM machines or have easy access to them, the subscription-based premium version (upgrade to a free 2-weeks trial) gives users access to expert features (video available here). With this premium version, users can set up their own AM machine and material portfolio, simulate and visualize nesting and slicing processes for a wide range of AM technologies, calculate exact production cost and production times, showcase the redesign potential of single parts and assemblies, and find the best-matching AM technology for uploaded parts. In addition to cost calculations, this software can generate internal AM price quotes based on quotation margins. All steps and settings can be configured to fine-tune results, which are then used to order, or export identified and qualified parts.

As a result, SelectAM’s platform saves time and facilitates the process to identify and qualify parts suitable for AM.

FAME Ecosystem member SelectAM was founded in 2020 by an international team of additive manufacturing experts and software developers. The Finnish startup makes the transition into AM easier. It allows you to screen and identify how your company can streamline production by analysing the supply chain, technical, economic, and (re)design potential of AM in your organization.

Originally published on 18 September.